Vibration Mount Selection Guide:

How we should decide to use which type/model of elastic mounts for our rotating machinery? Vibration and shock can cause a variety of problems for equipment, including:

- Reduced performance and accuracy

- Increased wear and tear

- Fatigue and failure

- Noise and discomfort

Vibration isolation and shock protection techniques can be used to protect equipment from these harmful effects.

When discussing vibration protection, it is useful to identify the three basic elements of dynamic systems: the equipment, the support structure, and the resilient member (elastic mounting).

The function of the elastic mounting depends on whether the equipment or the support structure is the source of the vibration and/or shock. If the equipment is the source, the elastic mounting reduces the force transmitted from the equipment to the support structure. If the support structure is the source, the elastic mounting reduces the dynamic disturbance transmitted from the support structure to the equipment.

The principle of isolation is the same in both cases. The elastic mounting, being a resilient element, stores the incoming energy at a time interval which affords a reduction of the disturbance to the equipment or support structure.

Vertical Vibration

Isolation is attained by maintaining the proper relationship between the disturbing frequency and the system's natural frequency. The natural frequency is the frequency at which the system will oscillate on its own if displaced from its equilibrium position. If the disturbing frequency is equal to the system's natural frequency, the system will be in resonance and the disturbance forces will be amplified rather than reduced. Therefore, it is important to select an elastic mounting with a natural frequency that is different from the disturbing frequency.

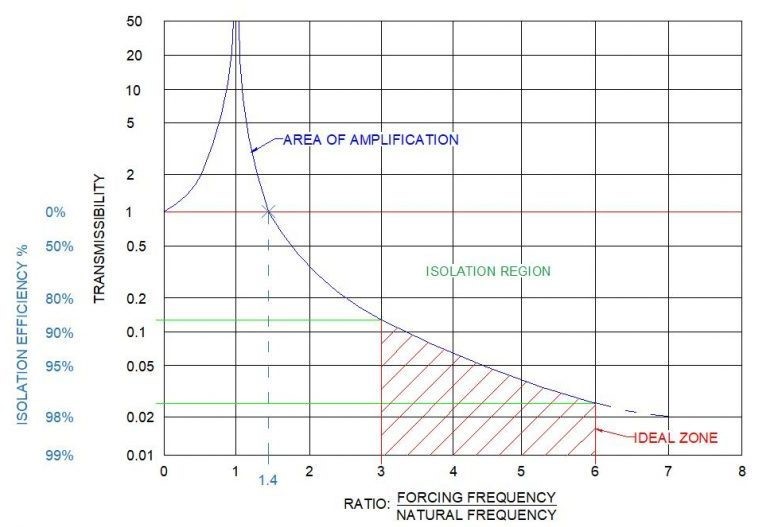

In Figure 1, the graph of transmissibility versus disturbing frequency ratio can be seen. Transmissibility is a measure of how much the vibration is amplified or attenuated by the elastic mounting. The graph shows that isolation begins when the disturbing frequency ratio is greater than 1.4.

Figure 1: Transmissibility versus disturbing frequency ratio graph

In conclusion, the effectiveness of an isolator in reducing vertical vibration depends on the proper relationship between the disturbing frequency and the system's natural frequency.

Damping

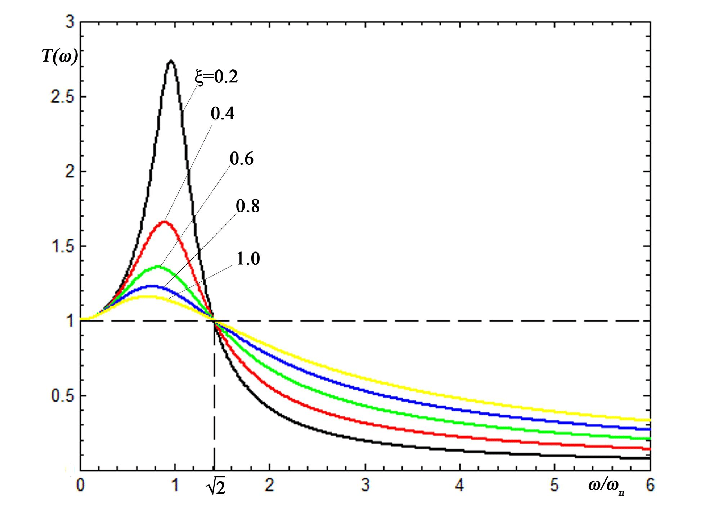

Damping is a force that opposes motion and helps to reduce vibration. It is advantageous when the mounted system is operating at or near its natural frequency because it helps to reduce transmissibility.

There is a positive correlation between damping and deflection, meaning that stiffer mountings will typically have less damping than softer mountings. If an elastic mounting with a higher degree of damping / higher deflection value is used instead, the amplification at resonance will be much less.

In Figure 2, the graph shows the relationship between damping and isolation efficiency. The graph shows that as damping is increased, isolation efficiency is somewhat reduced in the isolation region. However, the effect on transmissibility at resonance is much more significant.

In summary, damping is an important factor in vibration isolation. It helps to reduce the amplification of vibration at resonance, which can protect the mounted system from damage.

Structure-Borne Noise

Structure-borne noise is a type of noise that is transmitted through solid structures, such as the walls and floors of a building. It is caused by the vibration of machinery, equipment, or other objects.

An effective way to reduce structure-borne noise is to physically separate the solid structures and interpose a resilient material between them. This prevents the vibration forces from being transmitted and substantially reduces the noise.

Elastomeric materials, such as rubber, are generally best suited for structure-borne noise reduction. They are flexible and have inherent damping, which helps to avoid resonance at critical frequencies.

In summary, vibration isolation is an effective and low-cost way to reduce structure-borne noise. Elastic mountings are generally the best choice for this application.

Important parameters to select elastic mounting;

Related to equipment: weight, dimensions, center of gravity location, number and location of isolators, available space for isolators, fragility level of the equipment

Related to the dynamic inputs and outputs: level of vibration, level of shock, space limitations

If you are still unsure which elastic mounting to select, you can contact for assistance.